The U6 connection between the research centre Garching and the biotechnology site of the LMU Munich currently ends at the clinic Großhadern. For two years, LEONHARD WEISS GmbH & Co. KG has been working on an extension of the line of about one kilometre to Martinsried with a team of ten directors and specialised subcontractors.

Project information

- Customer:

- U-Bahn Martinsried Projektmanagement GmbH & Co. KG

- Construction period:

- 56 months

- Year of construction:

- 2022 – 2027

- Involved divisions:

-

Constructive civil engineering,

road construction,

track construction,

building renovation and mastic asphalt

Project description

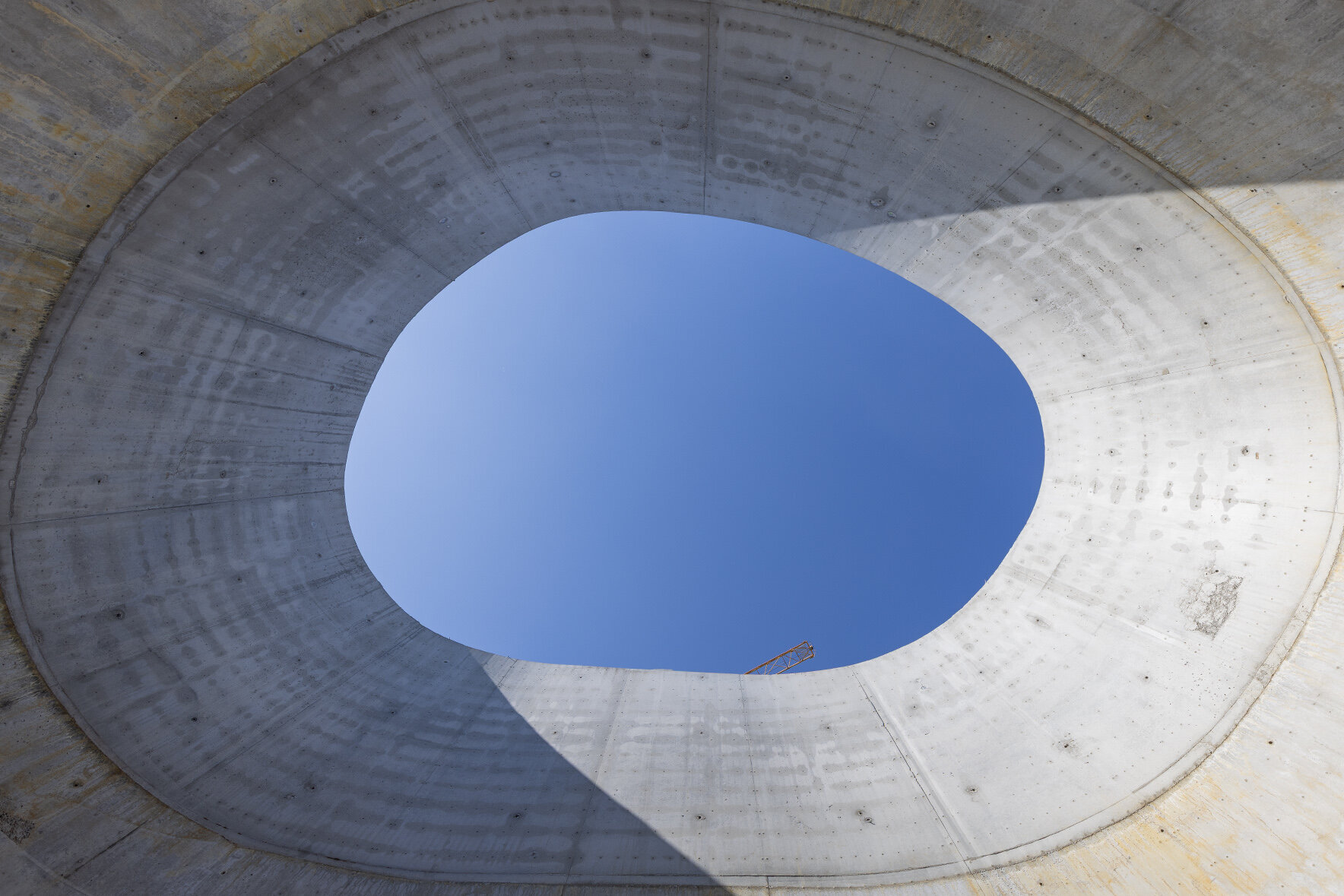

The scope of works ranges from earthworks and specialised underground engineering over ground water preservation up until complex concrete works for the new underground station. Since the symbolic ground-breaking ceremony in February 2023 the project is in steady progress. The excavation of the line, which includes a total of 340,000 m³ of soil and pebbles, is almost terminated. The tunnel route, which is constructed in open construction method and partly in cut-and-cover method, is lined with 3,757 overlapping bored piles and stretches over a width of 17-19 metres up to a depth of 20 metres. While the new station is already taking shape in the area of the western end of the construction site, the building shell for the connection to the existing underground train tunnel starts simultaneously at the eastern end of the construction site.

Innovative architecture to improve mobility

In order to be able to take the new station of the science line U6 into operation on schedule, various challenges must be mastered. One of these neuralgic points is the area around the crossing street “Am Klopferspitz“. For building the tunnel under the street, the experts of LEONHARD WEISS rely on a sophisticated cut-and-cover construction method, which avoids a complete shutdown of several months. In order to be able to produce the tunnel cover, the original position of the street was temporarily relocated to an alternative route to the west.

After the installation of bored piles, a two metres strong concrete cover was produced, which enables a quick reinstallation of the traffic route – while the tunnel construction can be continued underground.

The method is also used at Elisabeth-Stoeber-Straße, where the narrow building space required a relocation of the construction road from the north to the south. The experienced team, which has already realised numerous large projects in traffic intensive cities like Munich, Aachen, Cologne and Stuttgart, digs down underground step by step. A second set of struts made of steel tubes compensates the enormous earth thrust, before the remaining excavation and the installation of a reinforcing layer of underwater concrete are carried out. The final construction includes ground slab, walls and ceiling. In the sections, where the cut-and-cover method is applied, special ventilation tubes were integrated, in order to guarantee an optimum consolidation of the concrete – a further example of the technical expertise of the family-managed construction company in inner-city infrastructure construction.

State-of-the-art cushioning technology for sensitive research facilities

The non-ballasted track in the area of the station also requires technical methods adapted to the special local requirements. In the area of the LMU biology centre and the biotechnology centre IZB, where highly sensitive measuring devices are used, strict limit values are applicable – the resonance frequency in the area west of the street “Am Klopferspitz” may therefore not exceed 5 Hz. A highly developed mass-spring system ensures that vibrations transmitted by the concrete slab and secondary airborne sound are reduced to a minimum. The technical core is an innovative in-situ concrete bearing slab with elastic pointwise bearings, which stay accessible thanks to clever maintenance openings for being able to exchange the bearings any time. Specially developed sub-ballast mats are installed for smooth transitions between different stretches of the line – an overall concept, which combines high-tech research and public local traffic.

“Fairfaced concrete in civil engineering is a particular challenge due to the voluminous reinforced concrete construction parts – especially in tunnels in open construction method. There must be a careful coordination within the fairfaced concrete team and the structure must be realised together with all participants in the best way possible when it comes to quality and economic efficiency.”

Our success stories

Further successful construction projects

The extension of the urban railway to Martinsried

A mega project connects the science locations in Munich

Production of building shell at Rebstockbad Frankfurt

A new recreation paradise is being built at the metropolis