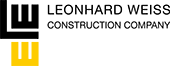

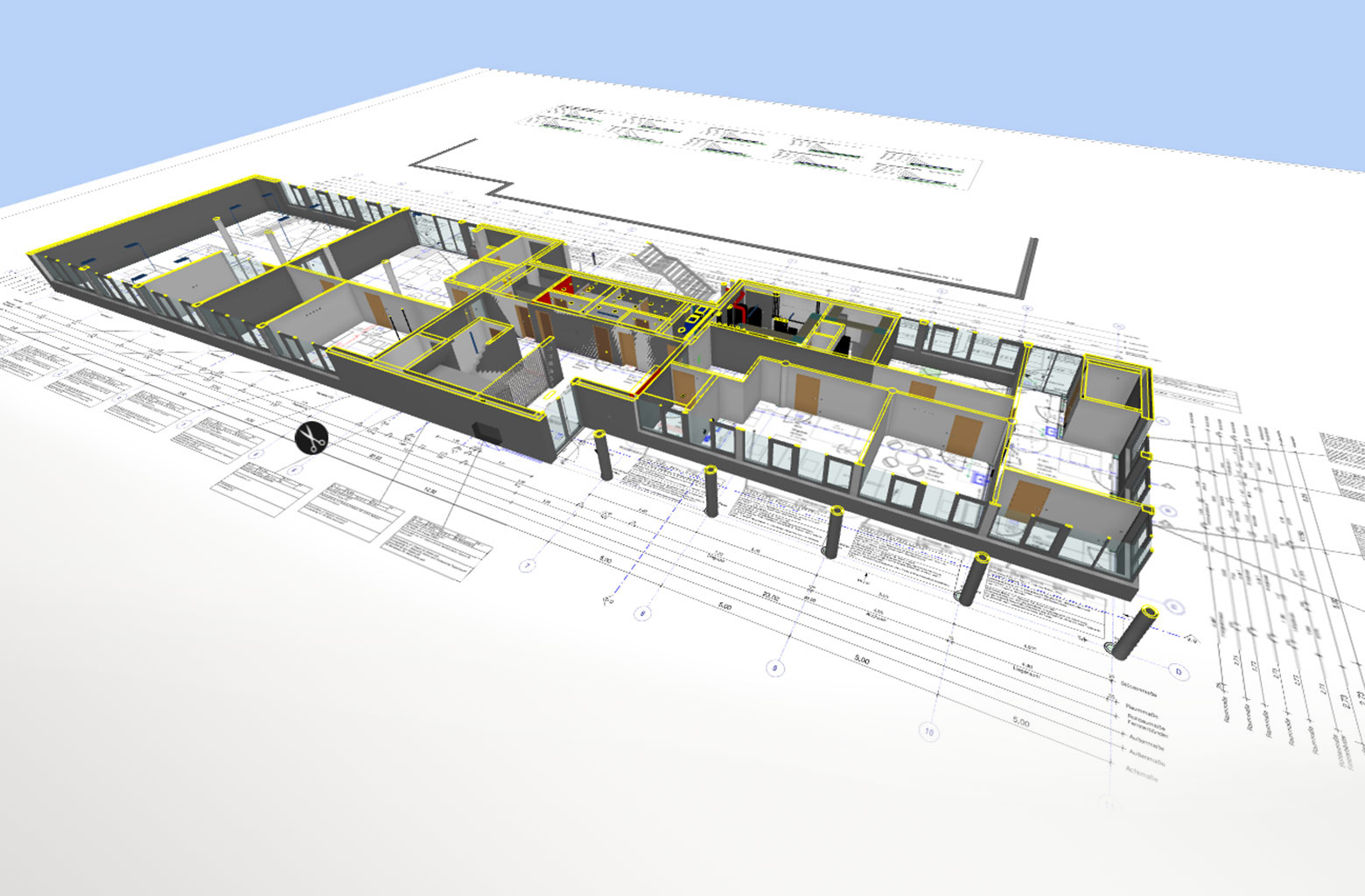

BIM Planning

Planning is carried out on the basis of a 3D model with intelligent construction parts. 2D plans, which are used, are always deduced from the 3D model. This model is the so-called Single Source of Truth. All project participants access the same consistent stock of data. Discrepancies in 2D plans, for example between lateral views and ground plan, can thus no longer occur.

EXCERPT OF OUR REFERENCES

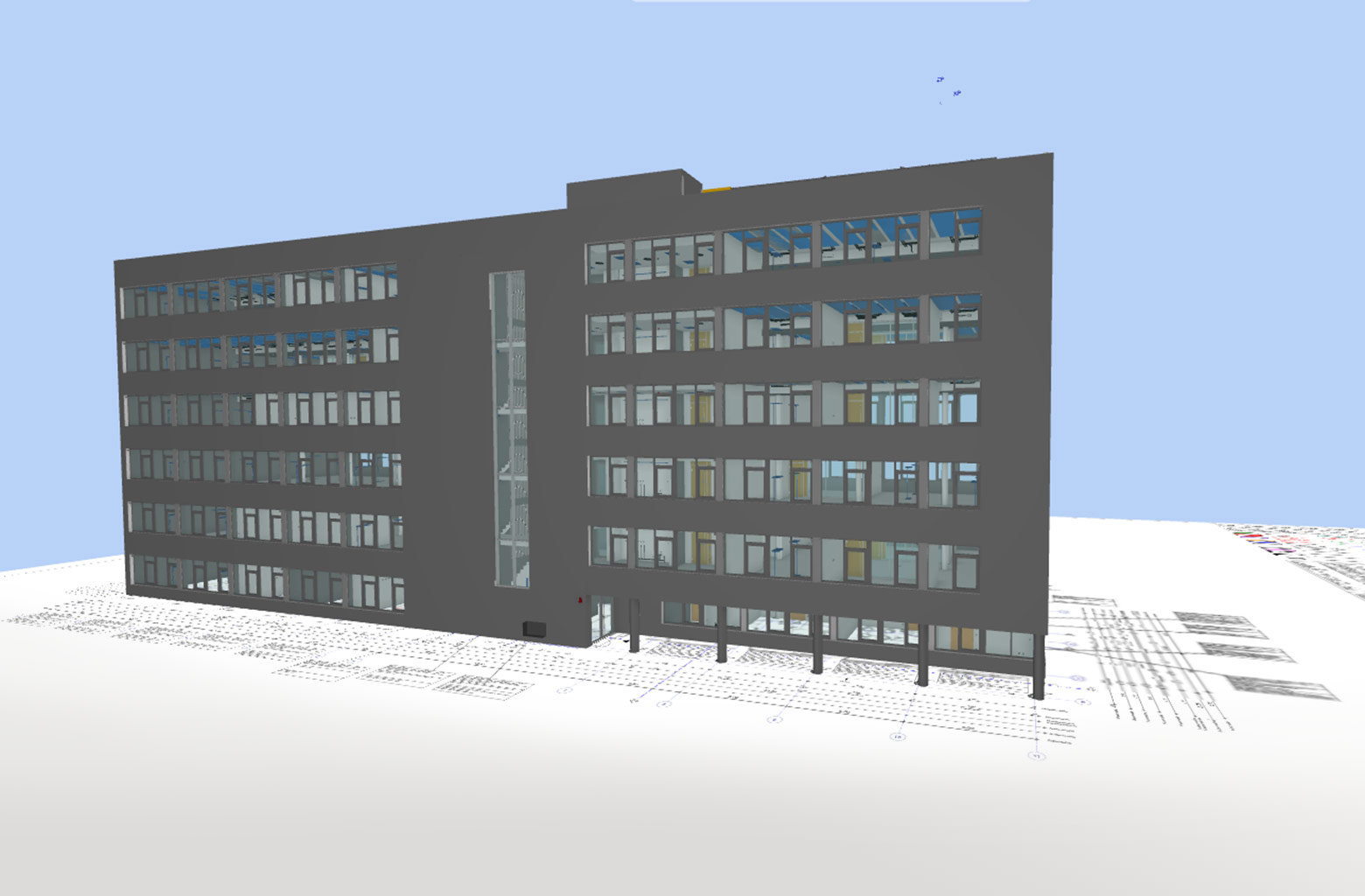

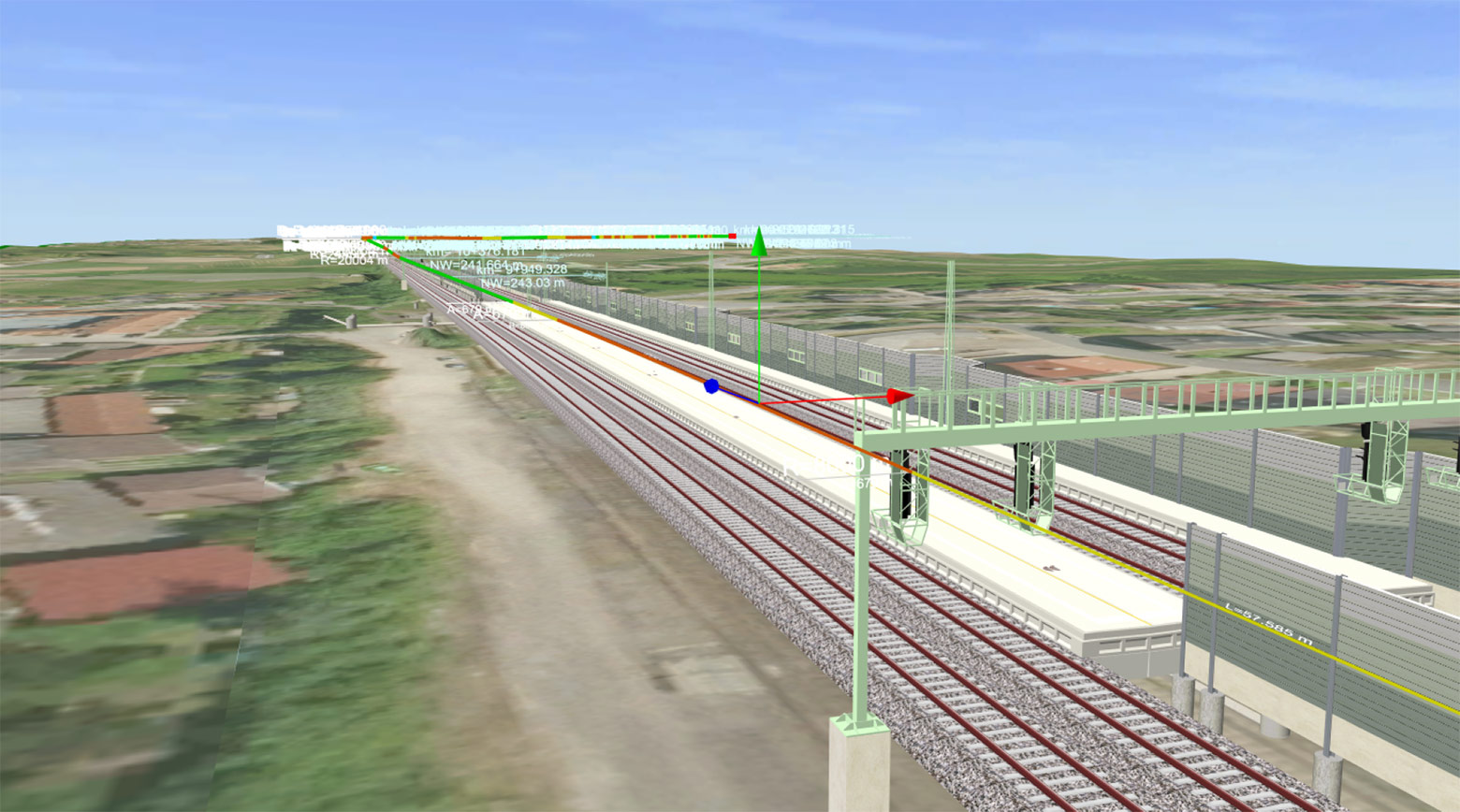

Increase in productivity and quality due to the development of an application methodology for complex track construction sites on the basis of BIM

In cooperation with a software producer, BIM methodology is currently being further developed in the pilot project VDE 8.1 BA2300 Hallstadt. The aim to successfully use standard solutions for the project phase, the execution of construction and the as-built documentation of railway infrastructure projects in the future is achieved using a linear 5D model by linking the data of all trades. In joint development work the BIM model is continuously extended with respect to the concrete use in construction. With the model collisions and conflicts in construction execution can be identified beforehand and solved, which generates an unprecedented adherence to schedules and costs for all project participants.

3D modelling

The compilation of the planning results of different trades in one 3D model requires the definition of handover scripts. Contrary to the traditional modelling, the data bases of the author systems are first joined to form a BIM model by means of scripts. Afterwards, changes in planning are automatically integrated into the model. A geometric collision check can then be carried out continuously without much effort.

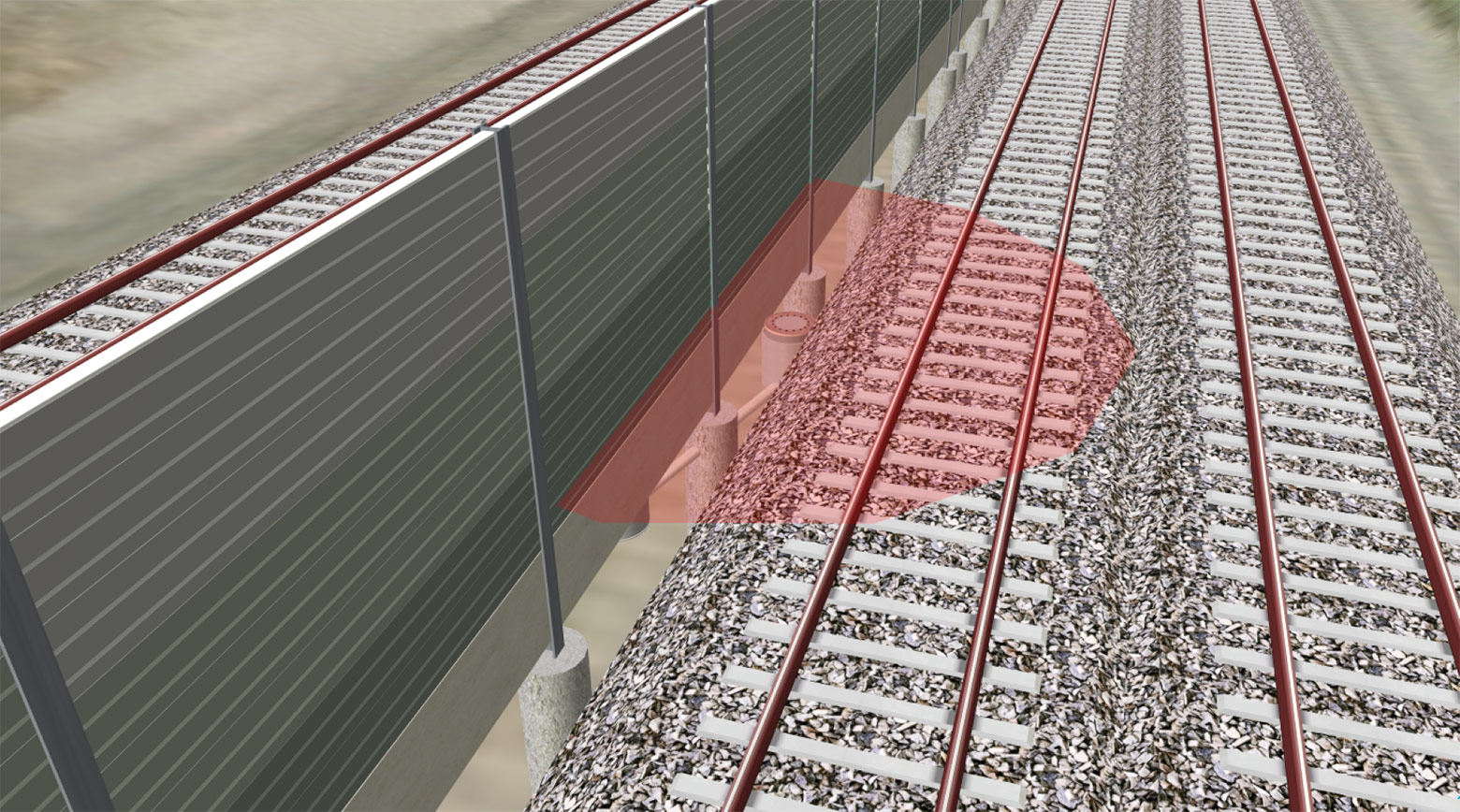

4D planning

In addition to the collision check during the construction period, the individual states of construction and the dismantling works in connection with them are analysed. For this task it is possible, for example, to examine individual trades or works on the model, in order to guarantee a smooth taking into operation. Furthermore, a stronger linking of logistics processes is pursued by 4D planning, which facilitates an optimised stock holding of construction materials, as well as their processing in due time.

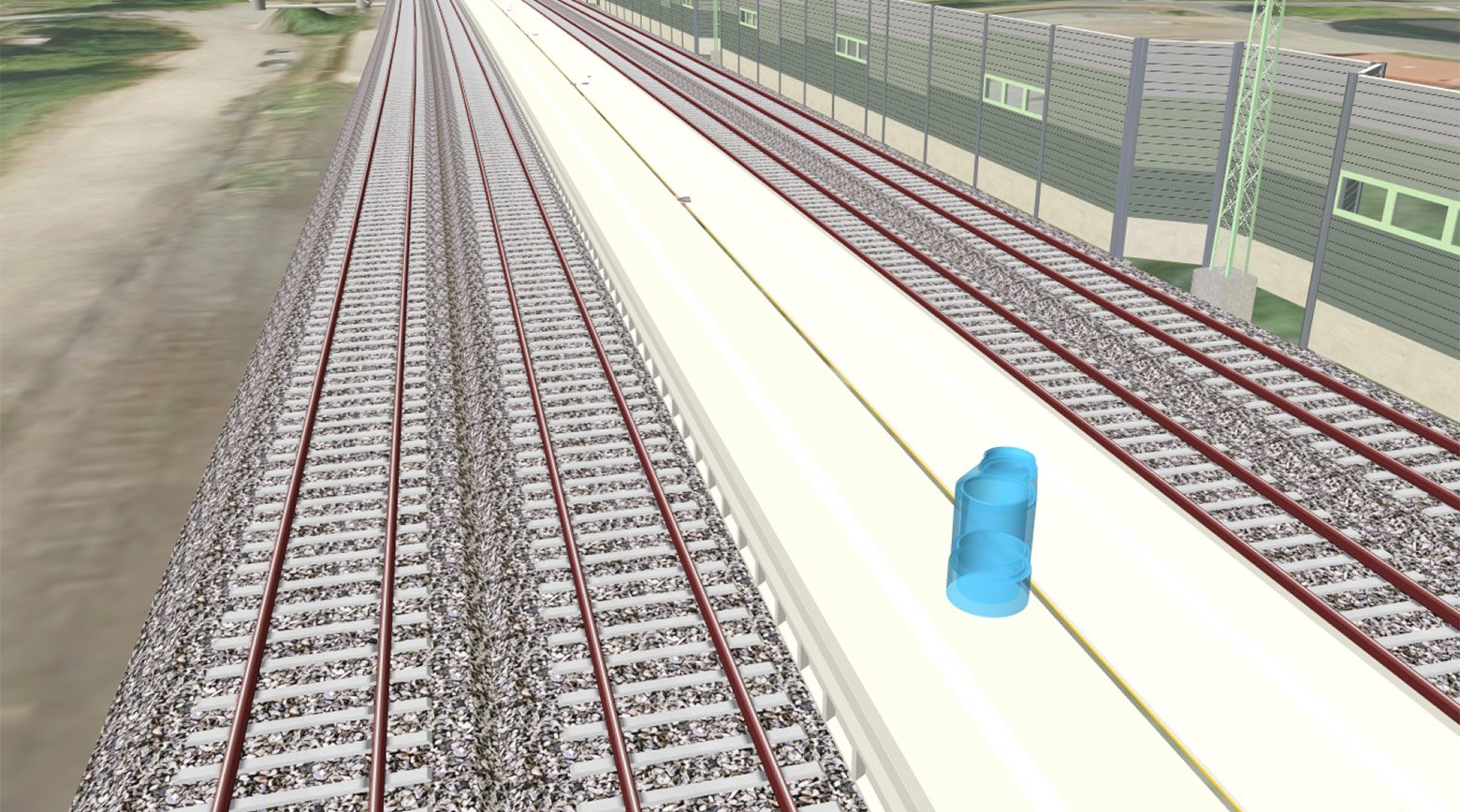

5D planning

For 5D planning the tender specification is linked to the individual construction parts, and every construction part is attributed a status display. The status indicates, if a construction part is ordered, for example, delivered or installed, which facilitates a detailed and automated monetary controlling of the construction site by means of a planned/actual comparison.

Platform for linking data from the construction environment

Based on the existing 5D model, data from the construction environment like pictures, documents or machine data, for example, are taken into account and linked to the model. This linking of data generates a documentation of the construction performance with hardly any gaps.