Blickle Rosenfeld

New construction customer centre with underground car park, extension administration

Customer: Blickle Räder + Rollen GmbH & Co. KGConstruction period: 15 months Year of construction: 2021–2022

- The company expands its administration building on the existing company premises. In addition to that, a new customer centre with underground car park is built. At the customer centre a new reception area is created with additional training and meeting rooms, as well as a highly modern test centre with test course for wheels and rollers. The new seven storey office building offers space for a total of 200 new workplaces and the creation of a modern office world. Adjacent to this building a new employee cafeteria is being built with over 250 seats indoors and outdoors.

- Steel: 2,200 t

- Concrete: 12,000 m³

- Gross floor area: 13,000 m² of useful space is being created

- Gross cubature: 50,000 m³

Blickle Rosenfeld

New construction PU production and gate H30

Customer: Blickle Räder + Rollen GmbH & Co. KGConstruction period: 12 months Year of construction: 2020–2021

- The company expands the production, assembly, and logistics space on the existing company premises by building a new PU production hall with high rack warehouse, three loading ramps, as well as several social and administrative areas. The industrial building expands over two storeys with two intermediate storeys and a basement and has as gross floor space of about 24,000 m².

- Steel: 4,764 t

- Concrete: 44,824 m³

- Gross floor area: 24,914 m²

- Gross cubature: 169,058 m³

New development of Durlacher Allee Karlsruhe

Customer: Albtal-Verkehrs-Gesellschaft mbHConstruction period: 11 months Year of construction: 2019–2020

- The new structure situated directly at Durlacher Allee includes a total of 3 buildings, construction part A, construction part B and the post room with a total of approximately 36,470 m² gross floor space, including an underground car park. The basement of the two buildings with a floor space of 6,012 m² is used a one large car park. The blocks of buildings are composed of 5-storey and 8-storey construction parts in reinforced concrete framework construction method with flat roofs, which are used as individual offices and open-plan offices. The post room is a bridge construction with a supporting steel structure made of welded steel profiles and is founded on drilled piles due to the existing railway track which must be overbuilt. The bridge construction consists of 4 storeys, which are also used as individual offices and open-plan offices, and it connects the new building, construction part A, to the existing building of the company AVG.

- Prefabrication of over 1,000 façade supports as prefabricated parts at the construction site in a field factory

- Installation of the façade supports with increased tolerances

- Very short construction period production of a storey with approximately 3,100 m² (ceiling, walls, supports) within 2 weeks

- 32 m long and 13.50 m wide steel construction, overbuilt with 4 storeys

- 6,012 m² underground car park as construction permeable to water with up to 1.30 m thick ground slabs and hydration channels

Particularities:

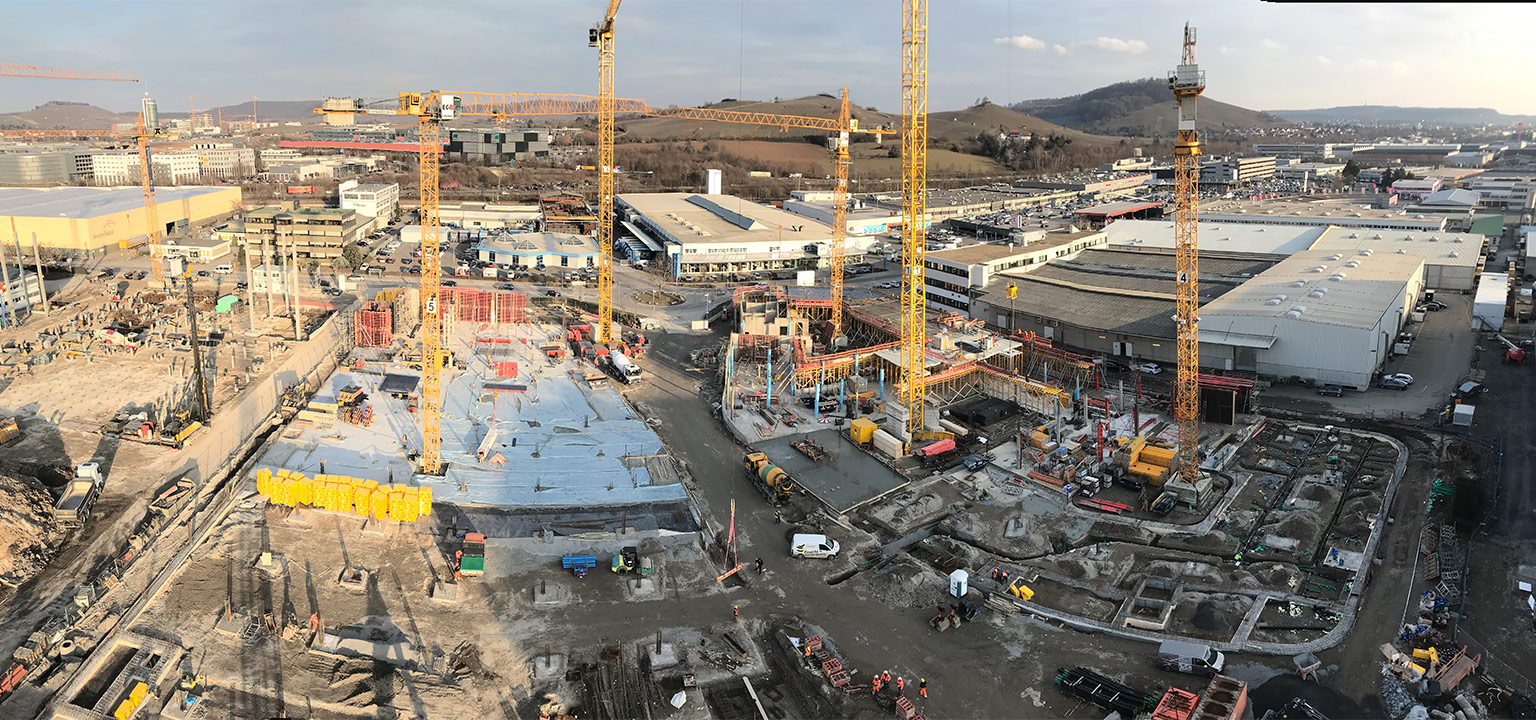

agnes Staufengalerie, Göppingen

Customer: Grundstückgesellschaft Einkaufszentrum Göppingen mbHConstruction period: 24 months Year of construction: 2019–2021

- The Frey-Centre formerly situated on the building plot was demolished except for the sub-basement and part of the existing car park. A tank for the sprinkler system and the engineering rooms were built into the remaining basement floors. The new building was built between the remaining outer walls and rises up to the 5th upper floor. The second construction phase started with a new floor slab from the level of the 1st basement floor; the existing sub-basement reaches up to the current 3rd basement floor. On about 23,000 m² the agnes Mall houses approx. 60 shops and 1,200 m² foodcourts with approx. 240 seats, as well as 700 parking spaces.

- Gross volume: approx. 152,779 m³

- Gross floor space: approx. 30,938 m²

- Concrete: approx. 20,400 m²

- Steel: approx. 3,400 t

- Brickwork: approx. 5,000 m²

QUANTITY

neue Balan Haus 27, München

Customer: Allgemeine SÜDBODEN Grundbesitz Verwaltung GmbHConstruction period: 16 months Year of construction: 2018–2020

- New construction of an office and industrial building including an underground garage with 350 parking spaces. The building consists of two basement floors, one ground floor, in which the restaurant/cafeteria is situated, and eight upper floors plus several structural parts on the top floor.

- Gross volume: approx. 171,141 m³

- Gross floor space: approx. 45,877 m²

- Concrete: approx. 27,965 m³ (probable billing quantity)

- Steel: approx. 4,268 t (probable billing quantity) incl. steel in prefabricated parts

- Brickwork: approx. 647 m³

- Prefabricated parts: stairs

- Concrete cubatures total: approx. 35,000 m³, approx. 8,500 m³ of which for the floor slab

- Structural steel total: approx. 3,400 t, 300 t of which for the floor slab

QUANTITY

Dairy Mechernich

Customer: Hochwald Foods GmbH, MechernichConstruction period: 13 months Year of construction: 2019–2020

- The consolidation of three dairies led to the new construction of the dairy company of Hochwald Foods GmbH in Mechernich-Obergartzem. In the future 800 million litres of milk will be processed into high quality long-life dairy products every year. The order consisted of fifteen buildings, which were built on a surface of about 4.5 hectares. The construction period amounted to 1 year. The construction project was a challenge because of the short construction period, the high walls with over 16 metres in some places, the installation of several thousand prefabricated parts and the production of concrete ceilings which were one metre thick.

- Concrete 45,000 m³

- Concrete prefabricated parts 2,200 pcs.

- Reinforcement steel 6,000 t

- Steel fibre 130 t

QUANTITY

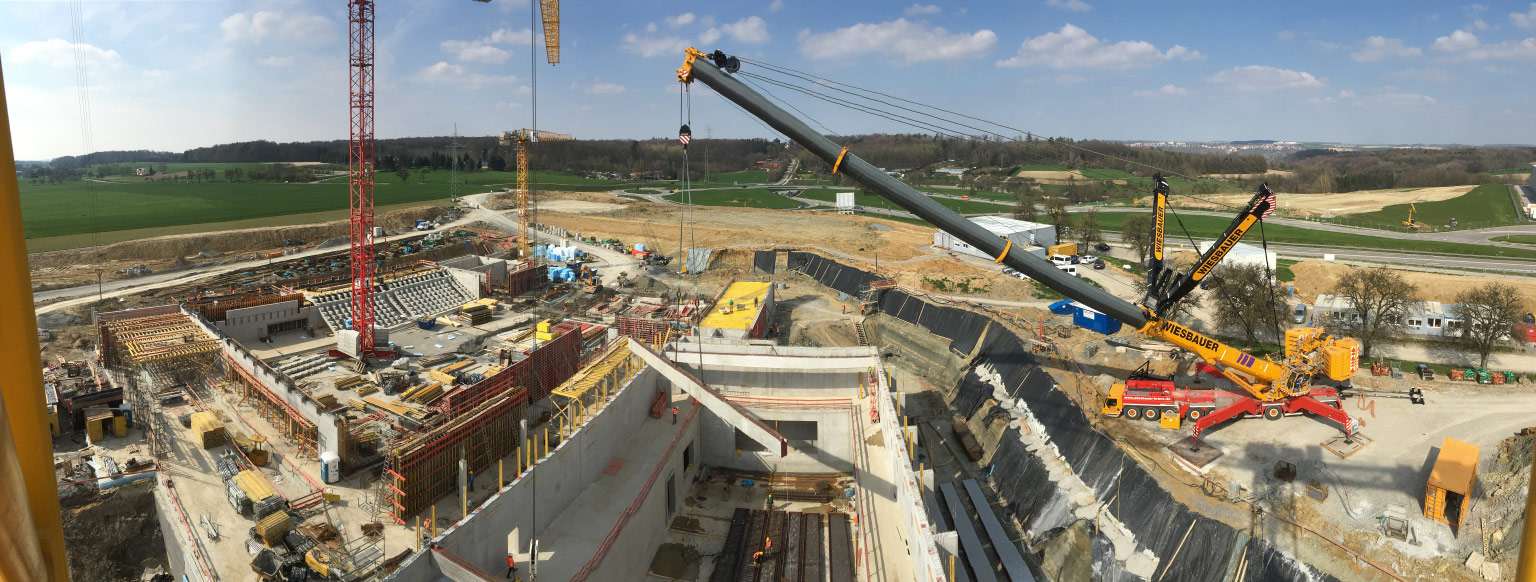

Neckarsulm, Lidl R36

Customer: Lidl Dienstleistung GmbH & Co. KGConstruction period: 15 months Year of construction: 2018–2020

- Complex office and industrial building incl. earth, drainage and sealing works from one source. Divided up into 3 building parts: office for 1,400 employees, rejection hall and connecting structure.

- Tight time schedule (building shell 12 months)

- Slim construction (ceilings, thickness=25 with reinforcements)

- Complex geometries, realisation with total station

- Height of ceilings up to 7 m in the hall, fair-faced concrete classes SB2 and SB3

- Heated drainpipes due to fatty media

- approx. 30,000 m³ concrete

- approx. 4,500 t steel

- approx. 650 pcs. prefabricated parts

Carmen-Würth-Forum, Künzelsau-Gaisbach

Customer: Adolf Würth GmbH & Co. KGConstruction period: 6 months Year of construction: January–June 2016 (Grandstand + add. works until April 2017)

- Congress and cultural centre, with event hall for about 2,700 persons and underground chamber music hall for 600 persons. Approx. 50% of the building is covered by earth. High architectural requirements with fair-faced concrete class 4. Many demanding details were developed together with architects, structural engineers and building owners and successfully put into practice within a short construction period under extreme weather conditions.

- Fair-faced concrete class 4, with sharp edges.

- Grandstand produced by LEONHARD WEISS made of prefabricated parts with sanded surface (in cooperation with SDC – Steinsanierung Denkmalpflege Crailsheim)

- Support walls of reinforced concrete with planned visible pouring lines and rough, non-skid surface

- Ceiling of the earth-covered chamber music hall with steel composite beams – span 21.50 m

- Due to the extreme weather conditions – backfilling of the schedule critical work space with liquid soil (in cooperation with LEONHARD WEISS Road construction Bad Mergentheim.)

- Approx. 23,000 m³ concrete

- Approx. 2,000 t steel

- Approx. 10,000 m² gross floor area

- Approx. 70,000 m² gross cubic space

PARTICULARITIES

QUANTITY