Renovation of the Waldhöhenfreibad Ebersbach an der Fils (open air swimming pool)

Customer: Stadt Ebersbach an der FilsConstruction period: 12 months Year of construction: 2022–2023

- Conversion of the non-swimmer pool incl. stainless steel lining (70 m²), new construction of the outdoor facilities around the paddling pool and non-swimmer pool (450 m²), plantation and greening works (100 m²), new construction of the access door with civil engineering and gate system, conversion of water technology for the entire open air swimming pool with new filter technology (4 filter facilities), pipe construction with earthworks (300 m PEHD pressure pipe), new control engineering, electric power lines (2,000 m), conversion of the pool water heating with new combi boiler, masonry and concreting works, new construction of pressure pipes, new walk-in manhole for pumps as in-situ concrete construction.

DGF Kathaparanlage, renovation powder drying plant, Göppingen

Customer: GELITA AG, GöppingenConstruction period: 4 months Year of construction: 2018–2019

- Demolition of the old ground slab in a hall with partial basement on the first floor. Installation of a seepage layer of gravel with irrigation system and of an insulation layer and a supporting ground slab. Production of a concrete base plate for the powder drying machine. Coating of the entire surface by our subsidiary LEONHARD WEISS Fußbodentechnik.

- Concrete demolition: 250 m²

- Concrete disposal: 162 t

- Concrete: 87 m²

- Reinforcement steel: 12 t

- Floor coating: 630 m²

QUANTITY

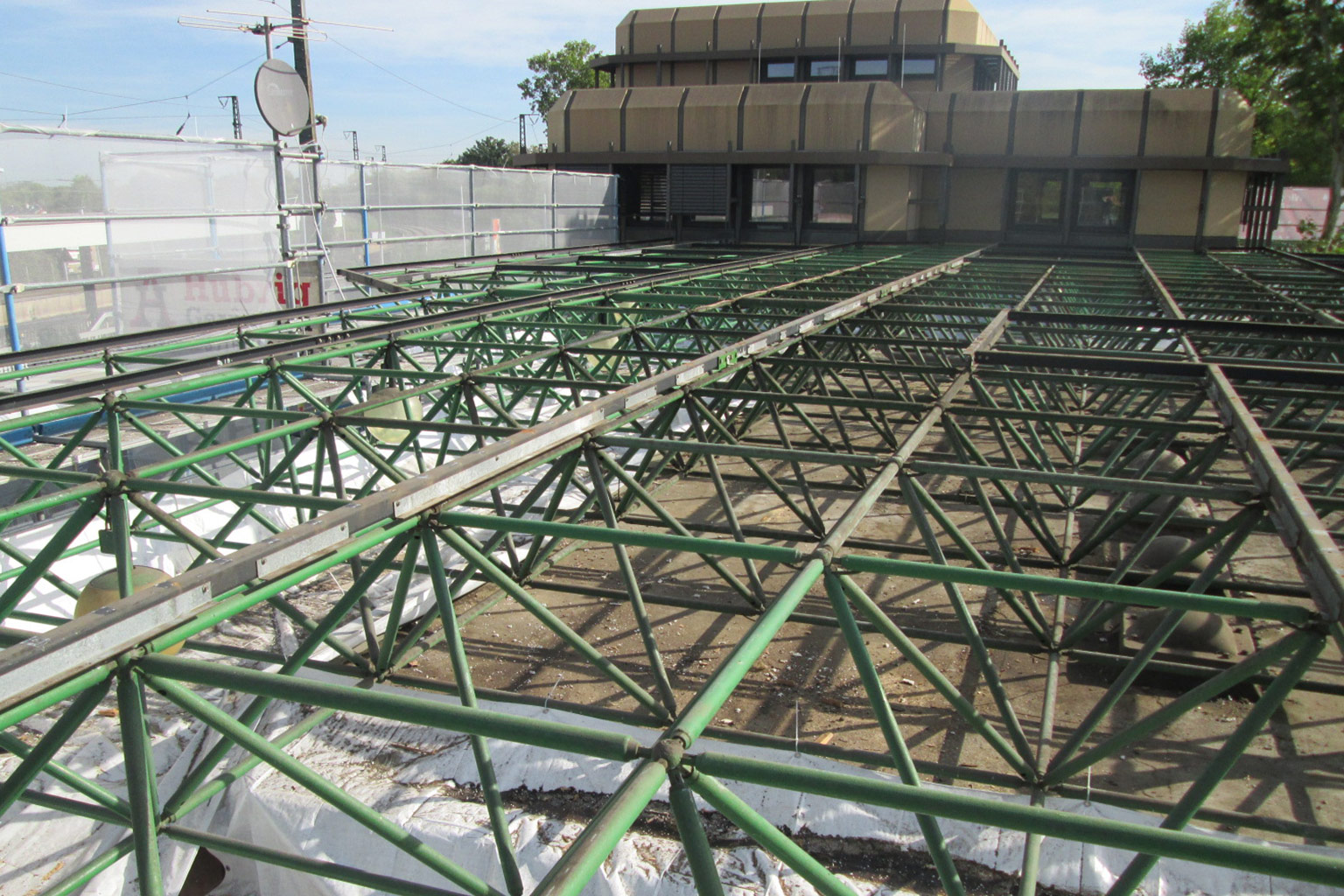

Station Waiblingen, renovation of the roof of the station forecourt including renovation of the mast locations

Customer: DB Station & Service AG, StuttgartConstruction period: 12 months Year of construction: 2018–2019

- The roof of the station forecourt which must be renovated is constructed as a steel tube modular system with ball knots, frame-members and supports with a laid-on roof of trapezoidal sheet, insulation, bitumen sealing, a layer of gravel and skylights. The bottom surface is covered by glass sheets. It was our assignment to entirely dismantle the roof and reconstruct it. The electric supply lines with lamps under the roof must be exchanged, as well as the lamp posts in the forecourt with underground engineering works.

- Dismantling and reconstruction of roof: 730 m² with 10 light domes

- Lamps: 28 pcs

- Lamp posts with double lamps: 14 pcs

- Cable: 1200 running metres

QUANTITIES

EMAG Salach, production of a new driveway to a factory hall

Customer: EMAG Salach GmbHConstruction period: 5 months Year of construction: 2018–2019

- The existing base slab of the driveway of the hall on the north-eastern side was lifted up from a level of approx. -1.20 m to the upper edge of the street level of the turning area built in front of the hall. It is now possible to drive into the hall without any difference in level. The former base slab was filled up with wet mix aggregate, and a new reinforced concrete base slab was produced on a separation layer.

- Steel: 10 t

- Concrete C30/37: 85 m³

- Base slab: 310 m²

- Ballast material: 200 t

- Connecting bolts to existing structure: 220 pcs

QUANTITIES

RegioRad DB Connect

Customer: Deutsche Bahn Connect GmbH, Frankfurt am MainYear of construction: Since April 2018, continuously

- Construction of bike stations with terminals for rental bikes, in different variations for bikes, pedelecs and load-carrying pedelecs. Places of installation in the area Stuttgart City and the surrounding municipalities. Execution of all works according to profiles, starting with excavating works, installation of foundations up to complete termination of the bicycle stands, including intern cabling works and marking works.

- Stations finished up to the present: 70 pcs Stuttgart City, 60 pcs surrounding municipalities

QUANTITIES

Renovation water power plant Tübingen

Customer: Stadtwerke TübingenConstruction period: June–August 2018

- A channel wall serving as overflow is renovated at the bypass weir of the water power plant. In order to do this, a coffer dam was constructed to hold back the river Neckar. The drainage structure was also created to prevent leakage water. Demolition works were carried out in the area of the bottom slab, facing wall and the wall flanning, as well as reinforced concrete works in these areas. Afterwards the auxiliary constructions and the coffer dam were dismantled.

- any risk of a potential pollution of water bodies must be prevented.

- Continuous water drainage of ground water and artesian water by means of pumps.

- Coffer dam made of Multibloc concrete blocks.

PARTICULARITIES

- 55 m³ demolition of concrete

- 10 t concrete steel

- 130 m³ concrete

QUANTITIES

Porsche EZW Renovation Building 4, Weissach

Customer: Porsche AGConstruction period: 12 months Year of construction: 2014–2015

- Energetic renovation and conversion was carried out without clearing the building during ongoing operations, an upper rotator was set up with an approximately 55 m radius in an atrium in very cramped conditions

WORK PERFORMED

- Site Equipment

- Precautions / dust protection walls

- Demolition / dismantling work Disassembly

- Earthworks and clearing work

- Concrete work

- Masonry

Elevated tank restoration, Börtlingen

Customer: Börtlingen MunicipalityConstruction period: 3 months Year of construction: 2015

- Demolition of the old water chamber, year of construction circa 1890, made of compressed concrete, transition from operations building into a new drinking water reservoir of concrete built as a passageway. Excavation and PE container filled, dry construction walls built of limestone blocks.

- Existing operations building had to be braced with structural steel before demolition of the old water chamber could begin. The new drinking water chamber was designed as PE water storage with approximately 100 m3 by the company Frank. Delivery was via special transport on a low-loader and it was moved with a truck crane, making a very short Construction period possible.

- Construction period duration was effectively only 22 working days

- Delivery of PE potable water storage on a low loader

- Diameter 3,500 mm

- Length 11,860 mm

- Volume 100 m3

- Weight 7 t

QUANTITIES