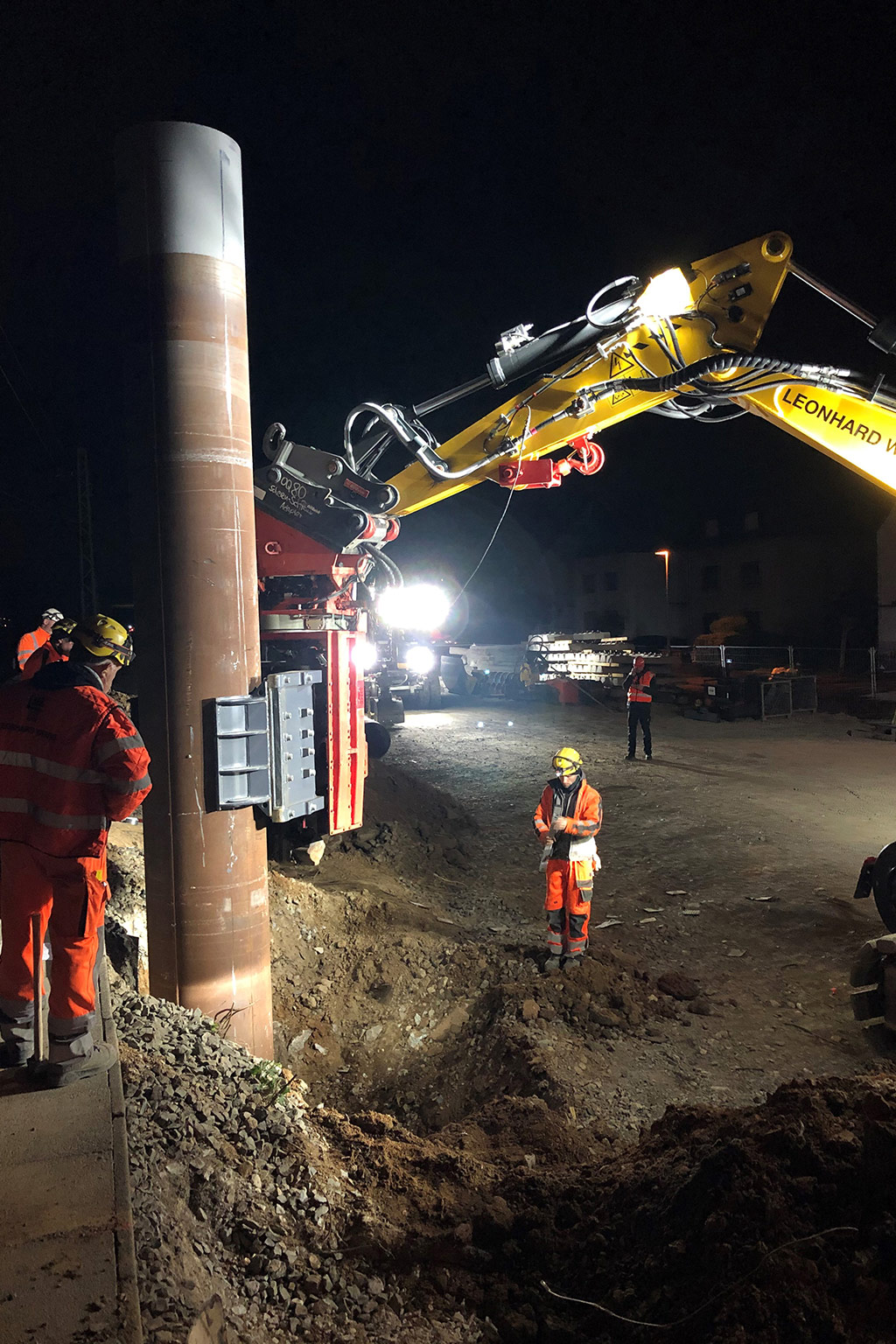

IECC Lahn

Customer: DB Netz AGConstruction period: 13 months Year of construction: 2023–2024

- Project characteristics: foundation and production of two signal brackets. Installation of control cabinets by means of a railway crane.

- 10 IECC incl. outside facilities

- approx. 220 track crossings

- 102 driven casing pipe foundations

- 42 monoliths

- 26 foundations on rock

- 42 Monolithen

- 2 signal brackets

Production of cable routes, track crossings, signal foundations and the laying of cables on a stretch of over 40 km between Wetzlar and Limburg:

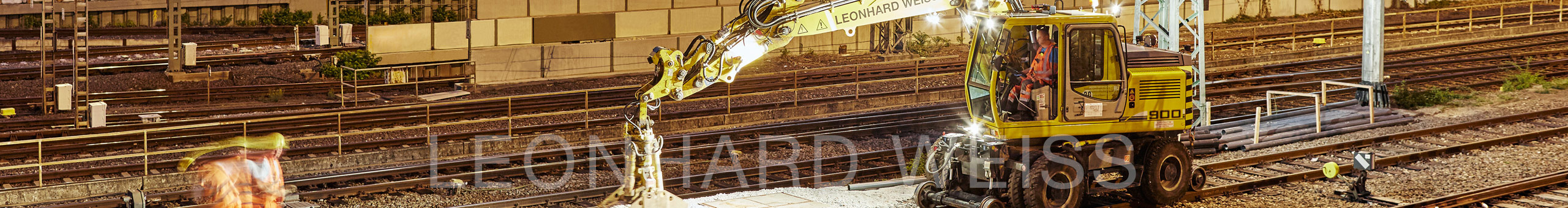

RRX PA 1.2. Leverkusen

Customer: DB Netz AGConstruction period: 36 months Year of construction: 2020–2023

- Upgrade of the approx. 3 km long section Leverkusen Chempark – Leverkusen Mitte from three to four tracks, incl. new construction of the entire railway construction, as well as all drainage facilities concerned. Approx. 4 km drainage pipelines, approx. 15,000 m² construction roads, approx. 12 km ´construction of new track incl. 17 new points, 1.5 km noise protection walls, as well as complete underground cable works and laying of cables for two IECC facilities

- new construction of 17 points, production of 12 km of track, production of 1,500 m noise protection walls, construction of 70 signal foundations, 10,000 m cable duct, one IECC outdoor facility.

Particularities

IECC Elm

Record-breaking construction period for Integrated Electronic Control Centre station Elm (Schlüchtern)

Customer: DB Netz AGConstruction period: 9 months Year of construction: 2020–2021

- Work force: 65 employees

- Use of technology: 12 road-rail excavators, railway construction train with flatbed wagons, ballast train, tamping machine with ballast plough

- Laying of cables for control, communication, and safety system/telecommunication: approx. 81 km

- Cable duct system concrete and glass fibre reinforced plastic approx. 18 km

- Cable assembly chutes sizes IV-X: 95 pcs.

- Signal foundations driven casing pipes: 35 pcs.

- Signal foundations concrete monolith: 25 pcs.

- Track crossings 4-12 wheel-track adhesion controls in concrete: 560 m

Breisgau S Bahn – Höllental Ost

There will be a lot of “coupling” in the future

Customer: DB Engineering & Consulting, KarlsruheConstruction period: 18 months Year of construction: May 2018–October 2019

- Electrification of the stretch, upgrade of the tunnel emergency response plan, upgrade of the stations under topographic difficulties. Entire planning works and overall coordination of the trades carried out by third parties. Lowering of the existing 5 tunnels, in order to make space for the overhead line inside the tunnel profile. Renovation of 3 stations and 4 stopping stations. Relocation of points in Löffingen and Döggingen, making it possible for trains to enter the station simultaneously from both directions. Flyovers in reinforced concrete construction method as well steel constructions (protection against contact, mast consoles on 4 existing viaducts) were produced for the overhead line. Telecommunication and 50 Hz facility, as well as underground cable engineering works for 3 IECC sites.

IECC Neustadt / Aisch - Iphofen

Challenges in the Region Mittelfranken

Customer: DB Netz AG, NurembergConstruction period: 30 months Year of construction:

November 2017–June 2020

- Complicated execution due to operative framework conditions on the construction site in stretches with speeds ≥200 km/h. New construction of outdoor facilities and outdoor installation for 3 locations IECC A modules. Construction of 3 emergency power stations at the IECC A locations. New construction of 4 signal brackets including foundation. Use and preparation of 35 km concrete cable conduit. New construction of 4,000 m concrete cable conduit and 30 crossings under the track by means of the pipe jacking and boring method. Conversion of point heating systems at the stations Neustadt/Aisch, Markt Bibart, Markt Einersheim, as well as the transfer points Langenfeld and Iphofen. New construction of approx. 40 point heating systems at existing points, production of new concrete switch cabinet for point heating, conversion and new construction of overhead line at the station Langenfeld and conversion of supply line at the station Markt Bibart. Approx. 150 km laying of cables for control, communication and safety system.

Breisgau suburban railway 2020 section Höllentalbahn West

Complex assignment in the area of the Germany’s steepest main line

Customer: DB Netz AG, KarlsruheConstruction period: 8 months Year of construction: 2018

- Complete shutdown of the lines 4300 and 4301 from Freiburg main station to Titisee and station Bärental. Thanks to the complete shutdown, works are being carried out simultaneously in partial areas on the overhead line, point heating, superstructure. Passages and rock consolidations are also newly constructed. Part of the lines only have one track, therefore all track-bound vehicles were equipped with a tracker, which makes it possible to locate the equipment on the construction site and coordinate it accordingly. Underground cable engineering with a total of 12 special foundations for signalling technology, laying of cables for control, communication and safety system, as well as telecommunication, production of building pits, IECC module buildings Himmelreich, Hinterzarten and Titisee, as well as their outdoor installations.

Integrated electronic control centre Osnabrück

Digital era for rail traffic around Osnabrück

Customer: DB Netz AG, HannoverConstruction period: 30 months Year of construction: April 2016–December 2019

- Important project for the construction of several electronic control centres along the line 2200, one of the largest control centres, 100 km railway track, main station Osnabrück has got an important junction station, execution is carried out in 6 phases of bringing into operation.

- Underground cable works for control, communication and safety system, 50Hz, electronic point heating system, emergency power supply works carried out in 24h shutdowns, as well as shutdowns < 3h during operation

- Approx. 82 km concrete cable conduit, approx. 540 cable construction chutes, approx. 535 km laying of cables, 407 km de-installation of cables, new construction of approx. 350 signal foundations, 16 pcs. new construction signal brackets, 5 pcs. demolition of signal bridges, 4,200m track crossings DN110-DN800, 11 outside facilities and development measures for integrated electronic control centre

ESTW Heidingsfeld

Modern railway control technology between Würzburg and Ansbach

Customer: DB Netz AG, MünchenConstruction period: 51 months Year of construction: 2014–2019

- Cable route system and cable installation for all technical equipment disciplines. Production of all signal foundations Renovation of equipment for power supply and switch-point heating. Construction of local overhead contact line control systems. Construction of signal brackets Outdoor facilities for new signal computer building. Challenging program of construction shutdown periods by the client.